Aluminum, often hailed as the “metal of the future,” has become an integral part of our daily lives, seamlessly woven into various aspects of modern society. From aerospace engineering to everyday consumer products, aluminum’s versatility and remarkable properties have earned it a special place in the materials landscape. In this blog post, we will explore what aluminum is, where it comes from, its diverse applications, and the eco-friendly journey of recycling this valuable metal.

What is Aluminum?

Aluminum is a lightweight, silvery-white metal known for its excellent strength-to-weight ratio and corrosion resistance. It is a chemical element with the symbol Al and atomic number 13 on the periodic table. Despite being the third most abundant element in the Earth’s crust, aluminum is rarely found in its pure form due to its strong affinity for oxygen. Instead, it is typically extracted from bauxite ore.

Extraction and Processing

Bauxite, a reddish-brown rock, is the primary source of aluminum. The extraction process involves refining bauxite to obtain alumina, which is then electrolyzed to produce aluminum. This energy-intensive process, known as the Hall-Héroult process, was a groundbreaking innovation that allowed for the mass production of aluminum in the late 19th century.

Applications of Aluminum

- Aerospace: Aluminum’s lightweight yet strong characteristics make it an ideal material for aircraft and spacecraft components. From fuselages to wing structures, aluminum plays a crucial role in the aerospace industry.

- Construction: Aluminum’s corrosion resistance and malleability make it a popular choice for construction materials. Windows, doors, roofing, and structural components often incorporate aluminum for durability and energy efficiency.

- Transportation: The automotive industry extensively uses aluminum for parts that require strength without adding excessive weight. This contributes to improved fuel efficiency and overall performance.

- Packaging: Aluminum’s ability to preserve the freshness of food and beverages, coupled with its recyclability, makes it a preferred material for packaging. Aluminum cans, foils, and containers are commonplace in the food and beverage industry.

- Electronics: Aluminum is widely used in electronics for its conductivity and heat dissipation properties. From smartphone casings to heat sinks in computers, its applications are diverse.

Recycling Aluminum

One of the most compelling aspects of aluminum is its recyclability. Recycling not only conserves natural resources but also requires significantly less energy compared to primary production. The aluminum recycling process involves:

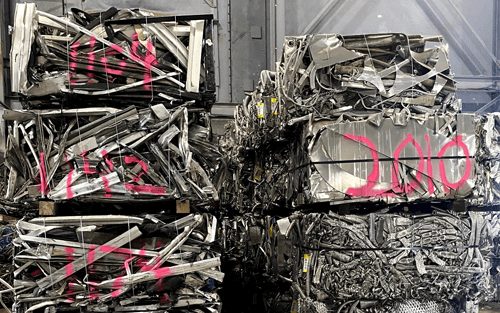

- Collection: Aluminum products, such as cans, foil, and packaging, are collected through recycling programs.

- Sorting: The collected aluminum is sorted to remove impurities and contaminants.

- Melting: The sorted aluminum is melted in a furnace, reducing it back to its liquid form.

- Purification: The molten aluminum undergoes purification processes to ensure the removal of any remaining impurities.

- Casting: The purified aluminum is cast into ingots or other desired forms for reuse in various applications.

From extraction to application and recycling, the path of aluminum highlights its versatile and adaptable elements. The recycling of aluminum demonstrates how industry and environmental considerations can harmonize, offering a glimpse into the remarkable journey of this metal. So, the next time you sip a drink from an aluminum can or admire your smartphone’s sleek design, pause to acknowledge the trajectory of this versatile material. You might be sipping from the recycled aluminum of a former airplane wing.